Reliability

Analysis of A Vacuum Tube Guitar Amplifier

EE – 710

Bill Rideout

August 7, 2007

Abstract

This project details a reliability analysis of a Gibson Gibsonette vacuum tube guitar amplifier. The goal of this analysis was to determine the reliability of the amplifier, determine the predominant failure modes, present methods to improve the amplifier availability and to identify design modifications that will improve reliability. The modeling program SPICE was utilized to analyze the amplifier circuitry and provide insight into its operation when various components failed. Much effort was expended finding and adjusting SPICE models for the vacuum tubes. Finally, an economic analysis of the options developed is presented.

Introduction

Some justification is in order to explain the consideration of vacuum tubes for any application in the twenty first century. Vacuum tube technology has been replaced by solid state electronics in almost all modern applications. Three exceptions for the present and foreseeable future are high power microwave applications, high end audio equipment, and guitar amplifiers. There are several reasons for the use of tubes in guitar amplifiers, some more rational and objective than others. Since the listening experience is ultimately subjective, and depends on the opinion of the listener, one could argue that many claims about the superiority of the sound of tubes are erroneous. However, there are marked differences in the design and operation of tube amplifiers as opposed to solid state amps. A significant factor in the preference for tube amplifiers among guitar players is that when guitars were first being amplified in the 1940’s and 1950’s, tube amplifiers were used exclusively. The sound of the distortion produced by tubes became the hallmark of the amplified guitar sound that remains to this day.

There are many theories and considerations on the difference

between the tube and solid state sound. Vacuum tubes generally progress into

non-linear operation with a ![]() like function while

transistors generally have more of a

like function while

transistors generally have more of a ![]() like function. Also, most tube amplifiers utilize an output

transformer which passes much of the second harmonic and attenuates higher

harmonics. In general, tube amplifiers produce many even harmonics which sound

more consonant to the ear. Transistor amplifiers, which frequently employ

negative feedback to produce a linear output, tend more toward the odd

harmonics when driven into non-linear operation. Conversely, many guitar

amplifiers use no negative feedback. Many contend that tubes have a “warmer”

sound and a softer transition into cutoff. In my humble opinion, this gradual

transition into cutoff is significant. Looking at the output signal of the

amplifier used for this project both on

an oscilloscope and simulated with SPICE, I was impressed with the variation in

waveform as the output tubes were driven further towards cutoff. I also think

that tubes just handle being massively overdriven better that transistors. Of

course, modern DSP technology can mimic tube distortion very well, but many

purists will continue to use tube amplifiers.

like function. Also, most tube amplifiers utilize an output

transformer which passes much of the second harmonic and attenuates higher

harmonics. In general, tube amplifiers produce many even harmonics which sound

more consonant to the ear. Transistor amplifiers, which frequently employ

negative feedback to produce a linear output, tend more toward the odd

harmonics when driven into non-linear operation. Conversely, many guitar

amplifiers use no negative feedback. Many contend that tubes have a “warmer”

sound and a softer transition into cutoff. In my humble opinion, this gradual

transition into cutoff is significant. Looking at the output signal of the

amplifier used for this project both on

an oscilloscope and simulated with SPICE, I was impressed with the variation in

waveform as the output tubes were driven further towards cutoff. I also think

that tubes just handle being massively overdriven better that transistors. Of

course, modern DSP technology can mimic tube distortion very well, but many

purists will continue to use tube amplifiers.

The amplifier I picked for this project is a Gibson model Gibsonette. Although the mainstay of vacuum tube guitar amplifiers were and are produced by Fender, Marshall, and Vox, the electronic circuitry is similar enough that generalizations from the study of the Gibson amplifier should apply to the others as well. I acquired this amplifier in the late 1970’s while in High School. I had to rewire the filter capacitors, apparently someone had tried to replace them and couldn’t figure how to get it back together. I’m guessing that this unit was manufactured sometime in the late 1950’s or early 1960’s. I chose this amplifier because I had access to it and had little qualms about taking it apart for study. Interestingly, there are many guitar players on the web that rave about this little amp, and I’ve read little negative about it. At any rate, it is still in use.

Amplifier Description

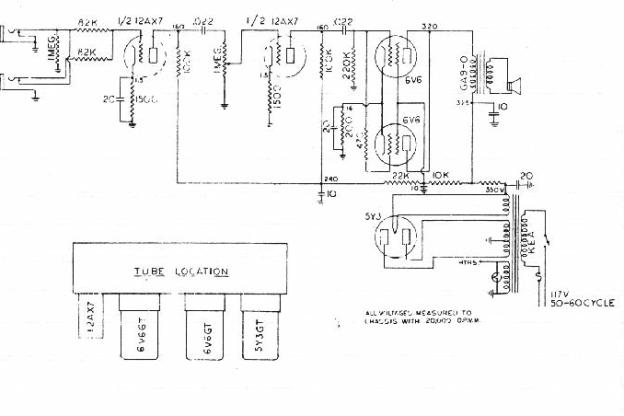

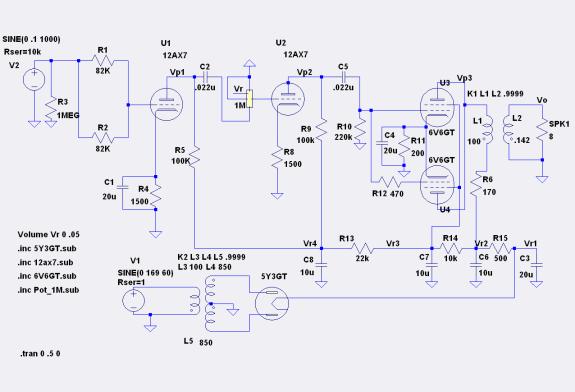

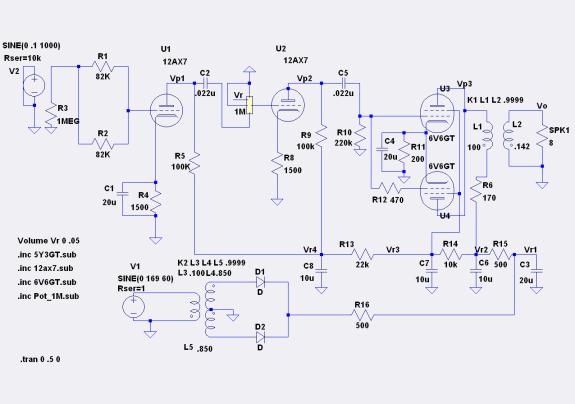

From research on the internet, I’ve found that Gibson made several versions of the Gibsonette amplifier. This particular amplifier uses a 12AX7 dual triode for the first and second amplifier stages and two 6V6GT beam power tetrodes in a single ended parallel configuration for the output stage. The vintage schematic found on the internet for this amp is shown in Figure 1. My SPICE schematic is shown in Figure 2.

Figure 1. Gibsonette Schematic

Figure 2. SPICE Schematic

Operation of this circuit is straight forward. The line in Voltage of 169 V is the peak voltage for 120 Vrms. The 5Y3 tube rectifies the 350 Vrms output from the power transformer and supplies the voltage divider ladder made up of R13,R14 and R15. This voltage divider supplies plate voltages for U1, U2, U3 and U4. Note that for SPICE it was convenient to treat U1 and U2 as separate tubes, they are actually both contained in a single 12AX7 tube. For that matter, the U designator was provided by SPICE so I just went with that. Filter capacitors C3, C6, C7, and C8 smooth out the DC voltage and reduce ripple. Cathode resistors R4, R8, and R11 provide a DC voltage at the cathode of U1, U2, U3 and U4 which is positive with respect to the 0 voltage found at the grids. This negative grid voltage biases the tubes into their operating region. Capacitors C1, and C4 provide and ac path to ground so that R4 and R8 to not provide negative feedback. Note that R8 is not bypassed. This version of spice did not have a symbol for a ¼” phone jack so this schematic represents the circuit with an instrument plugged into the top jack of the schematic shown in Figure 1. Resistors R3, R10 and the potentiometer ( R7) provide grid bias resistors.

This amplifier is designed to introduce distortion. The distortion observed at moderate signal levels would make it a terrible choice for a turntable (in keeping with the same era) amplifier. The input signal passes through R1 and/or R2 and is amplified by U1. Typically, very little distortion appears at this stage. With the shown input of 0.1 Vpeak the output at the U1 plate is about 5Vpeak indicating a voltage gain of 50. This signal is fed through coupling capacitor C2 which isolates the DC bias voltage from U1 to U2. The signal passes through the volume control, R7, to the grid of U2. On this schematic, the volume is set at about 2. The volume control potentiometer is described in greater detail in the SPICE section below. Output at the U2 plate at this setting is also about 5Vpeak indicating a unity voltage gain. At volume settings below this point there is actually attenuation in this stage. With an input of 0.1 Vpeak, this stage starts to produce noticeable distortion with the volume control set to about 3. The signal then travels through coupling capacitor C5 to the grids of U3 and U4. Presumably, R12 prevents noise problems that might occur from tying the grids of U3 and U4 together. The plates of U3 and U4 are connected together for a parallel single ended connection that is fed into the output transformer. As a side note, many higher power amps use a push-pull rather than a single ended configuration, but still have two tubes in parallel on each side. With the .1 Vpeak input and volume on 2, the voltage at the input to the output transformer is about 225Vpeak which provides about 8Vpeak on the output side of the transformer. Treating the speaker as a resistive load, the output power is about 4 watts. Noticeable distortion is observed at the output with the volume set at about 2 1/2. R6 is the input winding resistance of the output transformer.

Spice Simulation

Developing the Simulation

I chose Ltspice/SwitcherCAD III version 2.18s for this project. This program is offered free with no restrictions from Linear Technologies. Also, it has very usable schematic creation and schematic capture capabilities. If one wants to use their integrated circuits, it also offers models for their products. Models for passive components such as resistors, capacitors and inductors are provided. However, models for the vacuum tubes had to be developed. Fortunately, this version of spice does provide schematic symbols for both the triode and tetrode. The symbol can be placed in the circuit and then be linked to a sub- circuit for that tube model. I did have to create the symbol for the 5Y3 rectifier.

While considering this project, I searched the internet and found that there are indeed SPICE models that have been created for vacuum tubes. Two excellent sites are http://www.normankoren.com/Audio/Tube_params.html and http://www.duncanamps.com. Mr. Norman Koren has developed phenomenological equations from observed vacuum tube behavior as opposed to strictly applying the conventional Langmuir-Childs law analysis. He has also developed a MATLAB program to determine modeling parameters for specific tubes. I have found references to his work on other sites which lends some credibility to his effort. His model of the 12AX7 works very well and I used it directly in my SPICE simulation. A listing for this device is shown in Listing 1.

Listing 1. 12AX7 SPICE Model

.SUBCKT 12AX7 1 2 3 ; P G C; NEW MODEL (TRIODE)

+ PARAMS: MU=100 EX=1.4 KG1=1060 KP=600 KVB=300 RGI=2000

+ CCG=2.3P CGP=2.4P CCP=.9P ; ADD .7PF TO ADJ PINS, .5 TO OTHERS.

E1 7 0 VALUE=

+{V(1,3)/KP*LOG(1+EXP(KP*(1/MU+V(2,3)/SQRT(KVB+V(1,3)*V(1,3)))))}

RE1 7 0 1G

G1 1 3 VALUE={(PWR(V(7),EX)+PWRS(V(7),EX))/KG1}

RCP 1 3 1G ; TO AVOID FLOATING NODES IN MU-FOLLOWER

C1 2 3 {CCG} ; CATHODE-GRID

C2 2 1 {CGP} ; GRID=PLATE

C3 1 3 {CCP} ; CATHODE-PLATE

D3 5 3 DX ; FOR GRID CURRENT

R1 2 5 {RGI} ; FOR GRID CURRENT

.MODEL DX D(IS=1N RS=1 CJO=10PF TT=1N)

.ENDS

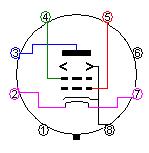

The tetrode model was another matter. While the models I tried accurately modeled gain and biasing of the device, the plate voltages for the 12AX7 were significantly lower than either the measured values from my amp or the values shown on the Gibson schematic. I finally figured out that the reason for this drop in voltage was the effect of the screen current on the voltage divider ladder that supplies the plate voltages to U1 and U2. To explain what was happening necessitated some understanding of the operation of the beam power tetrode. A drawing of a beam power tetrode is shown in Figure 3.

Figure 3. Beam Power Tetrode

(Image from Wikipedia under GNU license)

In this drawing, the screen is attached to pin 4, the plate is attached to pin 3, the grid is attached to pin 5, and the cathode is attached to pin 8. The purpose of the screen is to isolate the electric field of the plate from the electric field of the grid, thereby increasing gain. The screen is normally held at a DC voltage that is slightly less than that of the plate. In a normal tetrode, the screen attracts many of the electrons flowing from the cathode to the plate which results in a large screen current. This current can be up to 80% of the value of the plate current. In the power beam tetrode, the electrons flowing from cathode to plate are focused into a beam by elements that are electrically connected to the cathode. In this way, the effect of the screen on the grid and plate electric fields is still present while the number of electrons actually absorbed by the screen are greatly reduced, therefore dramatically reducing the screen current.

Interestingly, this is not the reason for the invention of the beam power tetrode. A problem with the regular tetrode is that at low signal levels, some electrons bounce off the plate and are absorbed by the screen thereby producing a “knee” in the response. The pentode solves this problem by inserting yet another element, the suppressor grid, between the screen and plate. The beam power tetrode solves this problem by focusing a beam of electrons to prevent electrons from the plate from flowing to the screen. The beam power tetrode was actually invented so that power tubes could be produced that did not violate the patent on the pentode.

The SPICE models that I found for the 6V6 beam power tetrode actually use a pentode model in which has a much higher screen current than the 6V6. This might have gone unnoticed had not this additional current and resulting voltage drop across R14 affected the plate voltages of the 12AX7. I divided the screen current in the 6V6 model by a constant to obtain a more reasonable screen current. The 6V6GT sub circuit model is shown in Listing 2. This model was obtained from the website http://www.audiobanter.com. This model works well for the amplifier simulation.

Listing 2. 6V6GT SPICE Model

*********************

*

* 6V6

* 28 Nov 2004

* new model based on measurements

* parameters revised 29 Nov 2004

*

**********************

..subckt 6V6GT A S G K

XV1 A S G K Pentode2

+ PARAMS: Ex=1.41031468452635 Mug=11.7888046293233 Mus=36.3212284562041

+ Kg1=1084.30402294001 Kp=36.0452435978759

+ Kvb=899.32403046434 Go=-0.467417459629955 Kd=0.000106867654972877

+ Exd=1.26175320982325 Exsd=0.425953018509995

+ C1=-2.85604234699625 A1=-5.68835011136307E-05 B1=3.49035244298882

+ X1=0.015108363529097 Y1=0.00926342558705693 Sr=0.198544592645026

+ Cgk=9P Cgs=5P Cga=0.7P Cak=7.5P

..ends 6V6GT

*******************

*

* Pentode model based on my investigations

* see Excel spreadsheets BeamPentodeModels.xls and Pentode Remote DL

* models.xls

*

* This model is for pentodes with remote cutoff grid characteristics and

* with

* knees that blend into a smooth line, ie a diode line, typical of Beam

* type tubes.

*

* this model therefore uses Korens method for total current, and diode

* lines.

*

* similart to Pentode1, but with revised Capture Ratio formula

*

* default parameters are for the 6V6

*

* RCM 2004 November 28

* 2004 Nov 29 revised capture ratio formula to correct problem when Vg

*> Vp or Vg > Vs

*

************************

..Subckt Pentode2 A S G K

+ Params: Ex=1.42596448566733 Mug=11.7822188645457 Mus=27.5137445137459

+ Kg1=1447.15506010676 Kp=36.3066403677756

+ Kvb=756.918578086785 Go=-0.557407825110845 Kd=0.000103636138847149

+ Exd=1.26335466904983 Exsd=0.431363489073363

+ C1= -0.940657929992395 A1=-0.000127738832949614 B1=1.72299135911867

+ X1=0.0345083152949822 Y1= 0.0177418846473534 Sr=0.0471284218217744

+ Cgk=9P Cgs=5P Cga=0.7P Cak=7.5P

* calculate the total space current based on Koren's triode equations,

* but with an equivalent triode plate voltage equal to the pentode Vs +

*Vp/Mus

En1 n1 0 VALUE={(V(A,K)/Mus+V(S,K))/Kp*LN(1+EXP(Kp*(1/Mug+(V(G,K)-Go)/SQRT(Kvb+(V(A,K)/Mus+V(S,K))**2))))}

Esc sc 0 VALUE={ (PWR(V(n1),Ex)+PWRS(V(n1), Ex))/(Kg1) }

* calculate the plate current capture ratio

Ecr cr 0 Value={If(V(A,K)<=0,0,C1+A1*V(A,K)+B1*((limit(V(A,G),1,1e6)**X1)/(limit(V(S,G),1,1e6)**Y1)))}

* the tentative plate current is total space current multiplied by capture

*ratio

Ept pt 0 Value={V(sc)*V(cr)}

* calculate the diode line current

Ed d 0 value={Kd*V(A,K)**Exd*V(S,K)**Exsd}

* the actual Plate current is the lesser of pt and d

Ep p 0 value={Min(V(d),V(pt))}

Ga A K value={V(p)}

* calculate the screen current capture ratio

* if Vg <= 0 then the screen gets all the remaining current, otherwise the

* grid gets some

Escr scr 0 value={Limit(if(V(G,K)>0,1-Sr*V(G,K),1),0,1)}

* screen current is anything not captured by the plate, multiplied by screen

*capture ratio

Esg sg 0 value={(V(sc)-V(p))*V(scr)}

*Gs S K value={V(sg)}

* Fudge

factor added to reduce screen current in line with observed behavior WFR

7-14-07

Gs S K value={V(sg)/5}

* grid current is anything not captured by the plate or the screen

Gg G K value={V(sc)-v(p)-V(sg)}

* interelectrode capacitances

C1 G K {Cgk}

C2 G S {Cgs}

C3 G A {Cga}

C4 A K {Cak}

..ENDS Pentode2

The potentiometer model adjusts the wiper resistance linearly by varying the reference input voltage from 0 to 1. The model for this sub circuit is shown in Listing 3.

Listing 3. 1M Potentiometer.

* POTENTIOMETER SUBCIRCUIT

*

* TERMINALS: 1-CCW , 2-WIPER, 3-CW

* WIPER POSITION VOLTAGE: 7-POS,8-NEG

*

.SUBCKT POT_1M 1 2 3 7 8

E_RA 1 4 VALUE = { V(7,8) * 1meg * I(VSENSE1) }

VSENSE1 4 5 DC 0V

RS 5 2 1

E_RB 5 6 VALUE = { (1-V(7,8)) * 1meg * I(VSENSE2) }

VSENSE2 6 3 DC 0V

.ENDS

Testing the Simulator

The results of measured voltages and values produced by the SPICE simulation for plates and cathodes at 0V input are shown in Table 1.

|

Plate

Volts |

U1 |

U2 |

U3 |

|

Gibsonette |

155 |

144 |

316 |

|

SPICE |

156 |

156 |

330 |

|

|

|

|

|

|

Cathode

V |

|

|

|

|

Gibsonette |

1.26 |

1.11 |

14.5 |

|

SPICE |

1.1 |

1.1 |

15.2 |

Table 1. Measured and Simulator Voltage

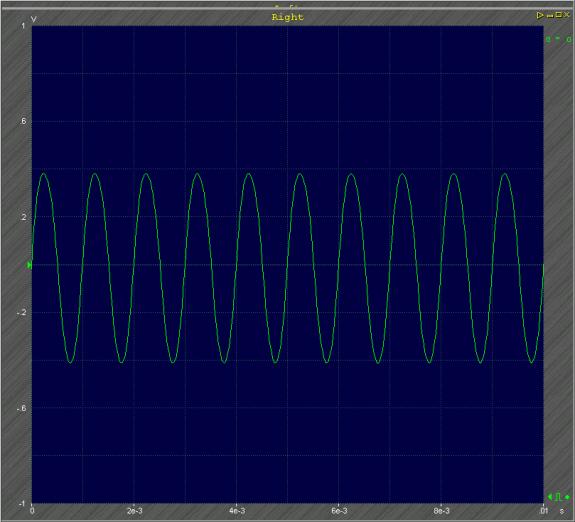

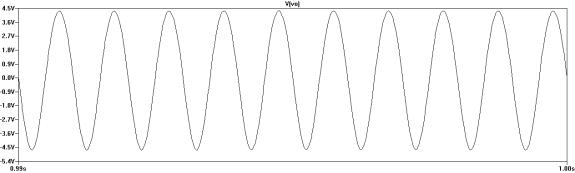

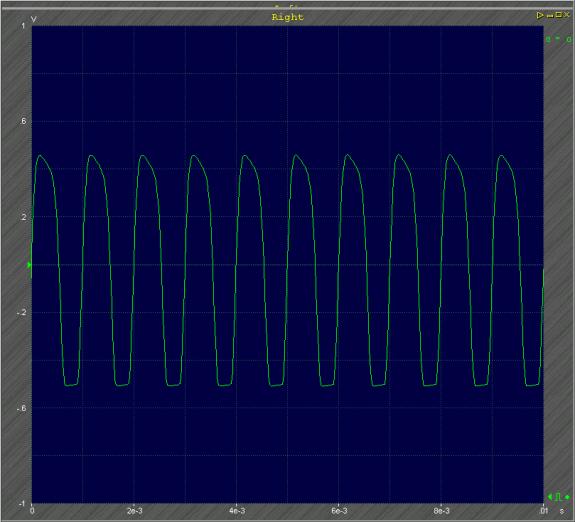

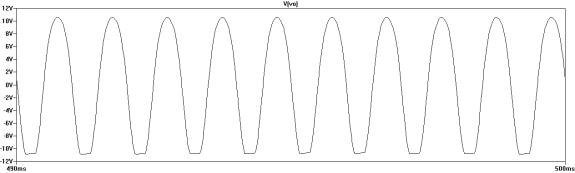

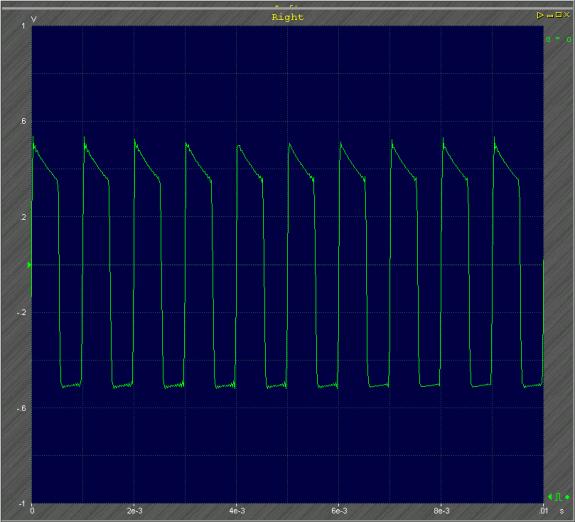

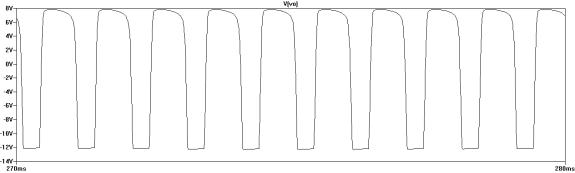

Measuring the output from my Epiphone Dot guitar on an oscilloscope, I found the output voltage at a low volume setting to be about 0.1 Vp-p and the output voltage at the maximum volume setting to be about 0.8 Vp-p. A 1kHz sine wave at 0.1V peak (0.2Vp-p) was used to test and compare the response of the amp to the SPICE simulation. The measured results shown below are cut and pasted from the program Oscillometer 5.60 Demo obtained from http://sbmelyoff.nm.ru . This program uses a computer sound card for its input. I resistively attenuated the signal to protect my soundcard so the voltages shown are not accurate. The voltages observed on an actual oscilloscope are close to those produced by SPICE, however, the primary intent of this comparison is to demonstrate the distortion characteristics. Figures 4 and 5 compare amp and SPICE outputs with R7 set to 25K, corresponding to a volume control setting of about 2. Figures 6 and 7 compare outputs with R7 set to 60K on the amp and 80k on SPICE roughly corresponding to a volume control setting of about 2 1/2. Figures 8 and 9 compare outputs with R7 set to 389K roughly corresponding to a volume control setting of about 5. The output waveforms from the amp itself and SPICE do differ and would not be adequate for other applications, such as developing a DSP simulation. However, they do show a good correlation between the SPICE simulator and the actual operation of the amplifier that can be used to model component failure.

Figure 4. Amp

Output at R7 Wiper to Ground at 25k, Volume at approx. 2

Figure 5. SPICE Output at R7 Wiper to Ground at 25k

Figure 6. Amp Output at R7 Wiper to Ground at 60k, Volume at approx. 2 ½

Figure 7. SPICE Output at R7 Wiper to Ground at 80k

Figure 8. Amp Output at R7 Wiper to Ground at 389k, Volume at approx. 5

Figure 9. SPICE

Output at R7 Wiper to Ground at 389k

Reliability Analysis

Covered Components

This analysis covers the reliability of resistors, capacitors, vacuum tubes and transformers. Items not covered are the ¼ “ input jacks, fuse, on/off switch and speaker. Reliability of these items, while significant, is in large part controlled by how the unit is used or abused and would be difficult to quantify.

Failure Mechanisms

The means by which individual components fail are considered and defined as follows:

Resistors

For this analysis, resistors are considered to fail open. Resistors typically fail as a result of excessive power dissipation which causes them to degrade into an open circuit.

Capacitors

Capacitors can fail open, short, or develop “leaks” which can be modeled by a parallel resistance. Older tube equipment frequently used capacitors made form paper foil and wax. These were prone to leak or short if penetrated by moisture. However, this particular amplifier does not employ these. Aluminum oxide electrolytic capacitors, as used in this equipment, can fail if not used for a very long time as the aluminum oxide requires DC current to maintain its integrity. Also, electrolyte can dry up causing capacitor failure. Capacitors can also fail when their rated voltage is exceeded.

Transformers

Transformers can fail shorted, partly shorted or open. They generally fail when the winding insulation melts or burns as a result of too much current.

Vacuum Tubes

In contrast to other circuit elements, vacuum tubes have a prescribed lifetime and can eventually be counted on too wear out. Typically, as the cathode ages, it will emit fewer and fewer electrons until the tube is unusable. Other methods of failure include shorting of internal elements, and loss of vacuum.

Inductive Failure Analysis

A bottom-up inductive approach was considered to determine the effects of individual component failure. The results are shown in Table 2. Where possible, the SPICE simulator was used to model the results of the failed component.

Component |

Excessive

Current /Power |

No

Amplification |

Low

Amplification |

Ring/Hum |

Noise |

No

Sound |

|

R1 Open |

|

Input 1 |

|

|

|

|

|

R2 Open |

|

Input 2 |

|

|

|

|

|

R3 Open |

|

|

|

|

X |

|

|

R4 Open |

|

X |

|

|

X |

|

|

R5 Open |

|

X |

|

|

|

|

|

R7 Open |

|

X |

|

|

|

|

|

R8 Open |

|

X |

|

|

X |

|

|

R9 Open |

|

X |

|

|

X |

|

|

R10 Open |

|

|

|

|

X |

|

|

R11 Open |

|

X |

|

|

X |

|

|

R12 Open |

|

|

X |

|

X |

|

|

R13 Open |

|

X |

|

|

X |

|

|

R14 Open |

|

X |

|

|

|

|

|

R15 Open |

|

|

|

|

|

X |

|

C1 Open |

|

|

X |

|

|

|

|

C1 Short |

|

X |

|

|

|

|

|

C2 Open |

|

X |

|

|

X |

|

|

C2 Short |

|

|

X |

|

|

|

|

C3 Open |

|

|

|

X |

|

|

|

C3 Short |

T1, U5 |

|

|

|

|

X |

|

C4 Open |

|

|

X |

|

|

|

|

C4 Short |

|

X |

|

|

|

|

|

C5 Open |

|

X |

|

|

|

|

|

C5 Short |

|

|

X |

|

|

|

|

C6 Open |

|

|

|

X |

|

|

|

C6 Short |

R15, U5, T1 |

|

|

|

|

X |

|

C7 Open |

|

|

|

X |

|

|

|

C7 Short |

R4 |

X |

|

|

|

|

|

C8 Open |

|

|

|

X |

|

|

|

C8 Short |

R13 |

X |

|

|

|

|

|

U1 Gain

loss |

|

|

X |

|

X |

|

|

U1 Noise |

|

|

|

|

X |

|

|

U1 Short |

|

X |

|

|

|

|

|

U2 Gain

loss |

|

|

X |

|

X |

|

|

U2 Noise |

|

|

|

|

X |

|

|

U2 Short |

|

X |

|

|

|

|

|

U3 Gain

loss |

|

|

X |

|

|

|

|

U3 Noise |

|

|

|

|

X |

|

|

U3 Sort |

T2.R11,R15,U5,T1 |

X |

|

|

|

|

|

U4 Gain

loss |

|

|

X |

|

|

|

|

U4 Noise |

|

|

|

|

X |

|

|

U4 Short |

T2.R11,R15,U5,T1 |

X |

|

|

|

|

|

U5 Gain

loss |

|

|

X |

X |

X |

|

|

U5 Noisy |

|

|

|

|

X |

|

|

U5 Short |

T1 |

|

|

|

|

X |

|

T1 Open |

|

|

|

|

|

X |

|

T1 Short |

|

|

|

|

|

X |

|

T2 Open |

|

|

|

|

|

X |

|

T2 Short |

U3, U4 |

|

|

|

|

X |

Table 2. Inductive

Failure Analysis

Reliability Calculations

For this analysis, system failure is considered to be any degradation of amplifier performance. Analysis of Table 2 and the circuit schematic yields the conclusion that, for the most part, failure of any single component will cause the amplifier to fail. For this reason, the initial reliability calculations are based on a parts count method. Failure rates for individual components were derived from MIL-HDBK-217F-Notice2.

Failure Rate Calculation

I created spreadsheets to calculate the failure rates of each component and then calculate the reliability for the amplifier. This facilitated the ability to immediately see the system sensitivity to de-rating of an individual component. All spreadsheets are provided in the accompanying excel file. Table 3 shows the failure rates for each component grouped by component type. For the resistors and capacitors, the criteria for the failure rate calculations are shown below the failure rate tables.

|

Resistors |

|

|

|

|

|

|

|

|||

|

Failures/106

hours

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|||

|

Resistor |

lambda-p |

lambda-b |

pi-T |

pi-P |

pi-S |

pi-Q |

pi-E |

|||

|

R1 |

0.047703 |

0.0037 |

1.5 |

0.068 |

0.79 |

10 |

16 |

|||

|

R2 |

0.047703 |

0.0037 |

1.5 |

0.068 |

0.79 |

10 |

16 |

|||

|

R3 |

0.047703 |

0.0037 |

1.5 |

0.068 |

0.79 |

10 |

16 |

|||

|

R4 |

0.119258 |

0.0037 |

1.5 |

0.17 |

0.79 |

10 |

16 |

|||

|

R5 |

0.343834 |

0.0037 |

1.5 |

0.44 |

0.88 |

10 |

16 |

|||

|

R7 |

0.047703 |

0.0037 |

1.5 |

0.068 |

0.79 |

10 |

16 |

|||

|

R8 |

0.119258 |

0.0037 |

1.5 |

0.17 |

0.79 |

10 |

16 |

|||

|

R9 |

0.308669 |

0.0037 |

1.5 |

0.44 |

0.79 |

10 |

16 |

|||

|

R10 |

0.308669 |

0.0037 |

1.5 |

0.44 |

0.79 |

10 |

16 |

|||

|

R11 |

1.142856 |

0.0037 |

1.5 |

1.3 |

0.99 |

10 |

16 |

|||

|

R12 |

0.119258 |

0.0037 |

1.5 |

0.17 |

0.79 |

10 |

16 |

|||

|

R13 |

0.308669 |

0.0037 |

1.5 |

0.44 |

0.79 |

10 |

16 |

|||

|

R14 |

0.78144 |

0.0037 |

1.5 |

1 |

0.88 |

10 |

16 |

|||

|

R15 |

2.02464 |

0.0037 |

1.5 |

1.9 |

1.2 |

10 |

16 |

|

Resistor |

Value |

Type |

Temp |

Power

diss |

Power

rated |

S |

Environ |

|

R1 |

82K |

RL |

70 C |

0.001 |

0.5 |

0.002 |

Gm |

|

R2 |

82K |

RL |

70 C |

0.001 |

0.5 |

0.002 |

Gm |

|

R3 |

1M |

RL |

70 C |

0.001 |

0.5 |

0.002 |

Gm |

|

R4 |

1500 |

RL |

70 C |

0.003 |

0.5 |

0.006 |

Gm |

|

R5 |

100K |

RL |

70 C |

0.1 |

0.5 |

0.2 |

Gm |

|

R7 |

1M Pot |

RL |

70 C |

0.001 |

0.5 |

0.002 |

Gm |

|

R8 |

1500 |

RL |

70 C |

0.006 |

0.5 |

0.012 |

Gm |

|

R9 |

100K |

RL |

70 C |

0.05 |

0.5 |

0.1 |

Gm |

|

R10 |

220K |

RL |

70 C |

0.05 |

0.5 |

0.1 |

Gm |

|

R11 |

200 |

RL |

70 C |

2 |

7 |

0.285714 |

Gm |

|

R12 |

470 |

RL |

70 C |

0.005 |

0.5 |

0.01 |

Gm |

|

R13 |

22K |

RL |

70 C |

0.05 |

0.5 |

0.1 |

Gm |

|

R14 |

10K |

RL |

70 C |

0.8 |

5 |

0.16 |

Gm |

|

R15 |

500 |

RL |

70 C |

5 |

10 |

0.5 |

Gm |

|

Capacitors |

|

|

|

|

|

|

|

|

|||

|

Failures/106

hours

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|||

|

Capacitor |

lambda-p |

lambda-b |

pi-T |

pi-C |

pi-V |

pi-SR |

pi-Q |

pi-E |

|||

|

C1 |

0.22792 |

0.00037 |

2.2 |

1.4 |

1 |

1 |

10 |

20 |

|||

|

C2 |

0.123728 |

0.00037 |

2.2 |

0.76 |

1 |

1 |

10 |

20 |

|||

|

C3 |

2.97216 |

0.00012 |

6 |

2.4 |

8.6 |

1 |

10 |

20 |

|||

|

C4 |

1.185184 |

0.00037 |

2.2 |

1.4 |

5.2 |

1 |

10 |

20 |

|||

|

C5 |

0.123728 |

0.00037 |

2.2 |

0.76 |

1 |

1 |

10 |

20 |

|||

|

C6 |

1.42272 |

0.00012 |

6 |

1.9 |

5.2 |

1 |

10 |

20 |

|||

|

C7 |

0.87552 |

0.00012 |

6 |

1.9 |

3.2 |

1 |

10 |

20 |

|||

|

C8 |

0.5472 |

0.00012 |

6 |

1.9 |

2 |

1 |

10 |

20 |

|

Value |

Type |

Temp |

Op

Volts |

Rated

V |

S |

Environ |

|

20u |

CP |

70 C |

2 |

25 |

0.08 |

Gm |

|

.022u |

CA |

70 C |

150 |

600 |

0.25 |

Gm |

|

20u |

CU |

70 C |

370 |

450 |

0.822222 |

Gm |

|

20u |

CP |

70 C |

20 |

25 |

0.8 |

Gm |

|

.022u |

CA |

70 C |

150 |

600 |

0.25 |

Gm |

|

10u |

CU |

70 C |

330 |

450 |

0.733333 |

Gm |

|

10u |

CU |

70 C |

280 |

450 |

0.622222 |

Gm |

|

10u |

CU |

70 C |

240 |

450 |

0.533333 |

Gm |

|

Tubes |

|

|

|

|

|||

|

Failures/106

hours

|

|

|

|

|

|||

|

|

|

|

|

|

|||

|

|

|

|

|

|

|||

|

Tube |

lambda-p |

lambda-b |

pi-L |

pi-E |

|||

|

12AX7 |

70 |

5 |

1 |

14 |

|||

|

6V6GT |

70 |

5 |

1 |

14 |

|||

|

5Y3 |

140 |

10 |

1 |

14 |

|

Transformers |

|

|

|

|

|

|||

|

Failures/106

hours

|

|

|

|

|

|

|||

|

Transformer |

lambda-p |

lambda-b |

pi-T |

pi-Q |

pi-E |

|||

|

T1 |

0.0798 |

0.014 |

1.9 |

3 |

6 |

|||

|

T2 |

0.1254 |

0.022 |

1.9 |

3 |

6 |

Table(s) 3. Calculated Failure Rates Using MIL-HDBK-217F

Criteria Used for Failure Rate Calculations

For the environmental component,![]() , the MIL-HDBK-217F designation Ground Mobile, Gm,

was used. To be conservative, I considered that the amplifier might be knocked

around or used in some rough environments. I chose an operating temperature of

70 degrees C to determine

, the MIL-HDBK-217F designation Ground Mobile, Gm,

was used. To be conservative, I considered that the amplifier might be knocked

around or used in some rough environments. I chose an operating temperature of

70 degrees C to determine ![]() as the tubes do generate heat and there is no little

ventilation for the enclosed components. For the learning component,

as the tubes do generate heat and there is no little

ventilation for the enclosed components. For the learning component, ![]() , I used the least conservative (best) number as the 12AX7

and 6V6 tubes had been in production for many years, even before this amp was

built. Commercial quality, the most conservative (worst) rating was used to

determine

, I used the least conservative (best) number as the 12AX7

and 6V6 tubes had been in production for many years, even before this amp was

built. Commercial quality, the most conservative (worst) rating was used to

determine ![]() as this is a commercially manufactured unit. Values for

as this is a commercially manufactured unit. Values for ![]()

were calculated using values either directly measured or determined by the SPICE simulation.

Determining Reliability

A reliability block diagram for the amplifier is shown in Figure 10.

Figure 10. Reliability Block Diagram

![]()

Table 4 shows a parts count component reliability for 8760 hours of use. As in

a “month of Sundays”, this represents 1 year’s worth of hours. If the amplifier

were used 2.4 hours per day, this would represent 10 calendar years. A constant

hazard rate is assumed so that the failure rate is an exponential function.

|

Capacitors |

lambda-p |

Reliability |

|

C1 |

0.22792 |

0.9980054 |

|

C2 |

0.123728 |

0.9989167 |

|

C3 |

2.97216 |

0.9742999 |

|

C4 |

1.185184 |

0.9896715 |

|

C5 |

0.123728 |

0.9989167 |

|

C6 |

1.42272 |

0.9876143 |

|

C7 |

0.87552 |

0.9923598 |

|

C8 |

0.5472 |

0.995218 |

|

|

|

|

|

Combined |

|

0.9365909 |

|

Tubes |

lambda-p |

Reliability |

|

U1 |

70 |

0.5416149 |

|

U3 |

70 |

0.5416149 |

|

U4 |

70 |

0.5416149 |

|

U5 |

140 |

0.2933467 |

|

|

|

|

|

Combined |

|

0.0466072 |

|

Resistors |

lambda-p |

Reliability |

|

R1 |

0.047703 |

0.9995822 |

|

R2 |

0.047703 |

0.9995822 |

|

R3 |

0.047703 |

0.9995822 |

|

R4 |

0.119258 |

0.9989558 |

|

R5 |

0.343834 |

0.9969925 |

|

R7 |

0.047703 |

0.9995822 |

|

R8 |

0.119258 |

0.9989558 |

|

R9 |

0.308669 |

0.9972997 |

|

R10 |

0.308669 |

0.9972997 |

|

R11 |

1.142856 |

0.9900385 |

|

R12 |

0.119258 |

0.9989558 |

|

R13 |

0.308669 |

0.9972997 |

|

R14 |

0.78144 |

0.993178 |

|

R15 |

1.31328 |

0.9885616 |

|

|

|

|

|

Combined |

|

0.9566759 |

|

Transformers |

lambda-p |

Reliability |

|

T1 |

0.9072 |

0.9920844 |

|

T2 |

1.4256 |

0.9875894 |

|

|

|

|

|

Combined |

|

0.9797721 |

Table 4. Parts Count Reliability

Figure 10.

Reliability Block Diagram

Design Modifications

Obviously, the failure rate of the vacuum tubes is the dominant reliability problem.

One tube that can be replaced with solid state devices with little or no effect on the quality of sound output is the 5Y3 rectifier tube. According to MIL-HDBK-217F calculations, this tube also has the highest base failure rate.

A circuit that replaces the 5Y3 rectifier with solid state diodes is shown in Figure 11.

Figure 11. Gibsonette Schematic with Solid State Diodes

Note that an additional series resistor is required since there is much less voltage drop across the solid state diodes than the 5Y3 rectifier tube.

Several other components can be de-rated to improve reliability. Modern aluminum oxide electrolytic capacitors are available with a 600V DC rating. Thus C3, C4, C6, C7 and C8 can be replaced with capacitors with the 600V rating. Replacing the power supply capacitors in an amplifier this old is probably a good idea anyway. These capacitors may very well be leaky and could cause serious damage if they shorted. R11 and R15 can be replaced with 10 watt and 20 watt resistors to improve their reliability.

Table 4 shows the new reliability calculations with the 5Y3 rectifier removed; D1,D2 and R16 added; C3, C4, C6, C7 and C8 replaced; and R11 and R15 replaced.

|

Tubes |

lambda-p |

Reliability |

|

U1 |

70 |

0.5416149 |

|

U3 |

70 |

0.5416149 |

|

U4 |

70 |

0.5416149 |

|

|

|

|

|

Combined |

|

0.158881 |

|

Capacitors |

lambda-p |

Reliability |

|

C1 |

0.22792 |

0.9980054 |

|

C2 |

0.123728 |

0.9989167 |

|

C3 |

0.6912 |

0.9939634 |

|

C4 |

0.250712 |

0.9978062 |

|

C5 |

0.123728 |

0.9989167 |

|

C6 |

0.5472 |

0.995218 |

|

C7 |

0.5472 |

0.995218 |

|

C8 |

0.30096 |

0.9973671 |

|

|

|

|

|

Combined |

|

0.9756623 |

|

Resistors |

lambda-p |

Reliability |

|

R1 |

0.047703 |

0.9995822 |

|

R2 |

0.047703 |

0.9995822 |

|

R3 |

0.047703 |

0.9995822 |

|

R4 |

0.119258 |

0.9989558 |

|

R5 |

0.343834 |

0.9969925 |

|

R7 |

0.047703 |

0.9995822 |

|

R8 |

0.119258 |

0.9989558 |

|

R9 |

0.308669 |

0.9972997 |

|

R10 |

0.308669 |

0.9972997 |

|

R11 |

1.015872 |

0.9911404 |

|

R12 |

0.119258 |

0.9989558 |

|

R13 |

0.308669 |

0.9972997 |

|

R14 |

0.78144 |

0.993178 |

|

R15 |

1.083456 |

0.9905538 |

|

R16 |

1.083456 |

0.9905538 |

|

|

|

|

|

Combined |

|

0.9506056 |

|

Transformers |

lambda-p |

Reliability |

|

T1 |

0.9072 |

0.9920844 |

|

T2 |

1.4256 |

0.9875894 |

|

|

|

|

|

Combined |

|

0.9797721 |

|

Diode |

lambda-p |

|

|

D1 |

1.08 |

0.9905838 |

|

D2 |

1.08 |

0.9905838 |

|

|

|

|

|

Combined |

|

0.9812563 |

Table 4. Improved Parts Count Reliability

Figure 11. Reliability Block Diagram

Vacuum Tube Replacement Strategy

This is a three fold improvement over the original reliability, but it is still rather low. Replacing the vacuum tubes on a regular schedule can dramatically improve the reliability. Table 5 shows tube reliability for 500 hours of operation.

|

Tubes |

lambda-p |

Reliability |

|

U1 |

70 |

0.9656054 |

|

U3 |

70 |

0.9656054 |

|

U4 |

70 |

0.9656054 |

|

|

|

|

|

Combined |

|

0.9003245 |

Table 5. Tube reliability with 500 Hour Replacement

The new system reliability is then:

This is almost a 20 fold improvement over the initial calculation.

Financial Considerations

Cost to Maintain Amp With No Design Improvement

Table 6 shows the projected maintenance costs based on reliability for 8760 hours of use. Components are not replaced until they fail. Tube and electrolytic capacitor pricing was obtained from http://thetubestore.com , transformer pricing from http://triodeelectronics.com, and all other components from Digi-Key.

|

Tubes |

Cost |

Labor |

Per

Year Hrs |

|

U1 |

$11.95 |

$0.00 |

$7.3277400000 |

|

U3 |

$19.95 |

$0.00 |

$12.2333400000 |

|

U4 |

$19.95 |

$0.00 |

$12.2333400000 |

|

U5 |

$9.95 |

$0.00 |

$12.2026800000 |

|

Total

Tube Cost |

$44.00 |

|

Component |

lambda-p |

Reliability |

Cost |

Labor |

Per

Year Hrs |

|

|||||||||||||

|

R1 |

0.047703 |

0.9995822 |

$0.18 |

$40.00 |

$0.0030087463 |

|

|||||||||||||

|

R2 |

0.047703 |

0.9995822 |

$0.18 |

$40.00 |

$0.0030087463 |

|

|||||||||||||

|

R3 |

0.047703 |

0.9995822 |

$0.18 |

$40.00 |

$0.0030087463 |

|

|||||||||||||

|

R4 |

0.119258 |

0.9989558 |

$0.18 |

$40.00 |

$0.0075218658 |

|

|||||||||||||

|

R5 |

0.343834 |

0.9969925 |

$0.18 |

$40.00 |

$0.0216862728 |

|

|||||||||||||

|

R7 |

0.047703 |

0.9995822 |

$0.18 |

$40.00 |

$0.0030087463 |

|

|||||||||||||

|

R8 |

0.119258 |

0.9989558 |

$0.18 |

$40.00 |

$0.0075218658 |

|

|||||||||||||

|

R9 |

0.308669 |

0.9972997 |

$0.18 |

$40.00 |

$0.0194683586 |

|

|||||||||||||

|

R10 |

0.308669 |

0.9972997 |

$0.18 |

$40.00 |

$0.0194683586 |

|

|||||||||||||

|

R11 |

1.142856 |

0.9900385 |

$2.38 |

$40.00 |

$0.9530870469 |

|

|||||||||||||

|

R12 |

0.119258 |

0.9989558 |

$0.18 |

$40.00 |

$0.0075218658 |

|

|||||||||||||

|

R13 |

0.308669 |

0.9972997 |

$0.18 |

$40.00 |

$0.0194683586 |

|

|||||||||||||

|

R14 |

0.78144 |

0.993178 |

$0.18 |

$40.00 |

$0.0492869837 |

|

|||||||||||||

|

R15 |

1.31328 |

0.9885616 |

$5.00 |

$40.00 |

$2.3008665600 |

|

|||||||||||||

|

C1 |

0.22792 |

0.9980054 |

$0.52 |

$40.00 |

$0.0415288474 |

|

||||||||||||

|

C2 |

0.123728 |

0.9989167 |

$0.57 |

$40.00 |

$0.0247119460 |

|

||||||||||||

|

C3 |

2.97216 |

0.9742999 |

$12.95 |

$40.00 |

$13.4867109888 |

|

||||||||||||

|

C4 |

1.185184 |

0.9896715 |

$0.52 |

$40.00 |

$0.2159500063 |

|

||||||||||||

|

C5 |

0.123728 |

0.9989167 |

$0.57 |

$40.00 |

$0.0247119460 |

|

||||||||||||

|

C6 |

1.42272 |

0.9876143 |

$12.95 |

$40.00 |

$6.4558480896 |

|

||||||||||||

|

C7 |

0.87552 |

0.9923598 |

$12.95 |

$40.00 |

$3.9728295936 |

|

||||||||||||

|

C8 |

0.5472 |

0.995218 |

$12.95 |

$40.00 |

$2.4830184960 |

|

||||||||||||

|

T1 |

0.9072 |

0.9920844 |

$39.99 |

$40.00 |

$12.7121363712 |

|||||||||||||

|

T2 |

1.4256 |

0.9875894 |

$59.95 |

$40.00 |

$29.9468378880 |

|||||||||||||

|

Component

Cost |

$72.78 |

Total maintenance cost $116.78

Table 6. Maintenance Cost for 8760 Hours of Operation

Cost to Maintain Amp With Design Improvement

Table 7 shows the projected maintenance costs based on reliability for 8760 hours of use. Components are not replaced until they fail.

|

Tubes |

lambda-p |

Reliability |

Cost |

Labor |

Per

Year Hrs |

|

U1 |

70 |

0.5416149 |

$11.95 |

$0.00 |

$7.3277400000 |

|

U3 |

70 |

0.5416149 |

$19.95 |

$0.00 |

$12.2333400000 |

|

U4 |

70 |

0.5416149 |

$19.95 |

$0.00 |

$12.2333400000 |

|

Total

Tube Cost |

$31.79 |

|

Component |

lambda-p |

Reliability |

Cost |

Labor |

Per

Year Hrs |

|

||||||||||||||||||||

|

R1 |

0.047703 |

0.9995822 |

$0.18 |

$40.00 |

$0.0030087463 |

|

||||||||||||||||||||

|

R2 |

0.047703 |

0.9995822 |

$0.18 |

$40.00 |

$0.0030087463 |

|

||||||||||||||||||||

|

R3 |

0.047703 |

0.9995822 |

$0.18 |

$40.00 |

$0.0030087463 |

|

||||||||||||||||||||

|

R4 |

0.119258 |

0.9989558 |

$0.18 |

$40.00 |

$0.0075218658 |

|

||||||||||||||||||||

|

R5 |

0.343834 |

0.9969925 |

$0.18 |

$40.00 |

$0.0216862728 |

|

||||||||||||||||||||

|

R7 |

0.047703 |

0.9995822 |

$0.18 |

$40.00 |

$0.0030087463 |

|

||||||||||||||||||||

|

R8 |

0.119258 |

0.9989558 |

$0.18 |

$40.00 |

$0.0075218658 |

|

||||||||||||||||||||

|

R9 |

0.308669 |

0.9972997 |

$0.18 |

$40.00 |

$0.0194683586 |

|

||||||||||||||||||||

|

R10 |

0.308669 |

0.9972997 |

$0.18 |

$40.00 |

$0.0194683586 |

|

||||||||||||||||||||

|

R11 |

1.015872 |

0.9911404 |

$2.38 |

$40.00 |

$0.8471884861 |

|

||||||||||||||||||||

|

R12 |

0.119258 |

0.9989558 |

$0.18 |

$40.00 |

$0.0075218658 |

|

||||||||||||||||||||

|

R13 |

0.308669 |

0.9972997 |

$0.18 |

$40.00 |

$0.0194683586 |

|

||||||||||||||||||||

|

R14 |

0.78144 |

0.993178 |

$0.18 |

$40.00 |

$0.0492869837 |

|

||||||||||||||||||||

|

R15 |

1.083456 |

0.9905538 |

$5.00 |

$40.00 |

$1.8982149120 |

|

||||||||||||||||||||

|

R16 |

1.083456 |

0.9905538 |

$5.00 |

$40.00 |

$1.8982149120 |

|

||||||||||||||||||||

|

C1 |

0.22792 |

0.9980054 |

$0.52 |

$40.00 |

$0.0415288474 |

|

|||||||||||||||||||

|

C2 |

0.123728 |

0.9989167 |

$0.57 |

$40.00 |

$0.0247119460 |

|

|||||||||||||||||||

|

C3 |

0.6912 |

0.9939634 |

$12.95 |

$40.00 |

$3.1364444160 |

|

|||||||||||||||||||

|

C4 |

0.250712 |

0.9978062 |

$0.52 |

$40.00 |

$0.0456817321 |

|

|||||||||||||||||||

|

C5 |

0.123728 |

0.9989167 |

$0.57 |

$40.00 |

$0.0247119460 |

|

|||||||||||||||||||

|

C6 |

0.5472 |

0.995218 |

$12.95 |

$40.00 |

$2.4830184960 |

|

|||||||||||||||||||

|

C7 |

0.5472 |

0.995218 |

$12.95 |

$40.00 |

$2.4830184960 |

|

|||||||||||||||||||

|

C8 |

0.30096 |

0.9973671 |

$12.95 |

$40.00 |

$1.3656601728 |

|

|||||||||||||||||||

|

T1 |

0.9072 |

0.9920844 |

$39.99 |

$40.00 |

$12.7121363712 |

|

|||||||||||||||||||

|

T2 |

1.4256 |

0.9875894 |

$59.95 |

$40.00 |

$29.9468378880 |

|

|||||||||||||||||||

|

D1 |

1.08 |

0.9905838 |

$11.97 |

$40.00 |

$4.5298310400 |

||||||||||||||||||||

|

D2 |

1.08 |

0.9905838 |

$11.97 |

$40.00 |

$4.5298310400 |

||||||||||||||||||||

|

Component

Cost |

$72.78 |

Total maintenance cost $104.57.

Table 7.

Maintenance Cost With New Design

Additional Cost of Scheduled Tube Replacement

Table 7 shows the cost of replacing the tubes every 500 hours for 8760 hours of use.

|

Tubes |

Per

500 hr |

Per

8760 hrs |

|

U1 |

$11.95 |

209.364 |

|

U3 |

$19.95 |

349.524 |

|

U4 |

$19.95 |

349.524 |

|

|

|

|

|

Total |

|

908.412 |

Table 7. Cost of Scheduled Tube Replacement

Cost of Design Modification

Estimated cost of the design modification is shown in Table 7. The maintenance cost savings for 8760 hours of use due to the design modification is $116.78 - $104.57 = $12.21. The cost saving per hour use is $12.21/8760 = $0.0013428. Dividing this into the cost of the upgrade - $171.26/$0.0013428 = 127,539 hours or 146 years to break even on cost. Clearly the modifications should only be considered to increase reliability.

|

Component |

Cost |

|

R11 |

$5.00 |

|

R15 |

$5.00 |

|

R16 |

$5.00 |

|

C3 |

$12.95 |

|

C4 |

$0.52 |

|

C6 |

$12.95 |

|

C7 |

$12.95 |

|

C8 |

$12.95 |

|

D1 |

$11.97 |

|

D2 |

$11.97 |

|

Labor |

$80.00 |

|

|

|

|

Total |

$171.26 |

Table 8. Cost of Design Modification

Conclusions

Reliability analysis provides a valuable tool to evaluate the operation of existing systems. In this project, quantitative analysis of the Gibsonette amplifier provided insight on when the failure rate of the vacuum tubes would likely cause a system failure. Although the 500 hour replacement schedule presented is probably excessive, it demonstrated the principle of replacement to dramatically improve system reliability. Also, the tools developed here can be used to help determine the cost/benefit analysis of approximately when the tubes should be replaced.

This project used spreadsheets to evaluate the effects of time and component de-valuation to determine their overall effect on system reliability. Other tools can be used to provide a more in depth study, but the principle of performing this type of interactive analysis was demonstrated. This analysis quantified the dramatic effect of time on components with high failure rates.

As a reality check, the reliability analysis recommended work on the power supply and replacing the electrolytic capacitors of the amplifier. In general, this is a good idea as these capacitors frequently cause problems as the become leaky or short. Some purists scoff at the idea of replacing the rectifier tube with a solid state device. However, it would make the amplifier more reliable. Plug in solid state replacements are available commercially. As for tube replacement, one vacuum tube vendor, Audio Research http://www.audioresearch.com , recommends replacement of tubes before they fail, giving the failure rate of preamplifier tubes (12AX7 in this case) at 5000 hours and power tubes (6V6GT in this case) at 2000 hours.

Bibliography

Valve Amplifiers, Morgan Jones, Elsevier Ltd., Oxford, UK. 2003

The Cool Sound of Tubes, Eric Barbour, IEEE Spectrum, August 1998

Practical Reliability Engineering, Fourth Edition, Patrick O’Conner, John Wiley and sons 2006

Testing of Digital Systems, Jha and Gupta, Cambridge University Press, Cambridge, UK. 2003

Fault

Tree Handbook with Aerospace Applications, Dr.

Michael Stamatelatos, NASA 2002

MIL-HDBK-217F Notice 2, US Department of Defense, December 1991

http://www.normankoren.com/Audio/Tube_params.html